PRODUCT DETAILS

Eco-friendly natural raw materialK-CNF

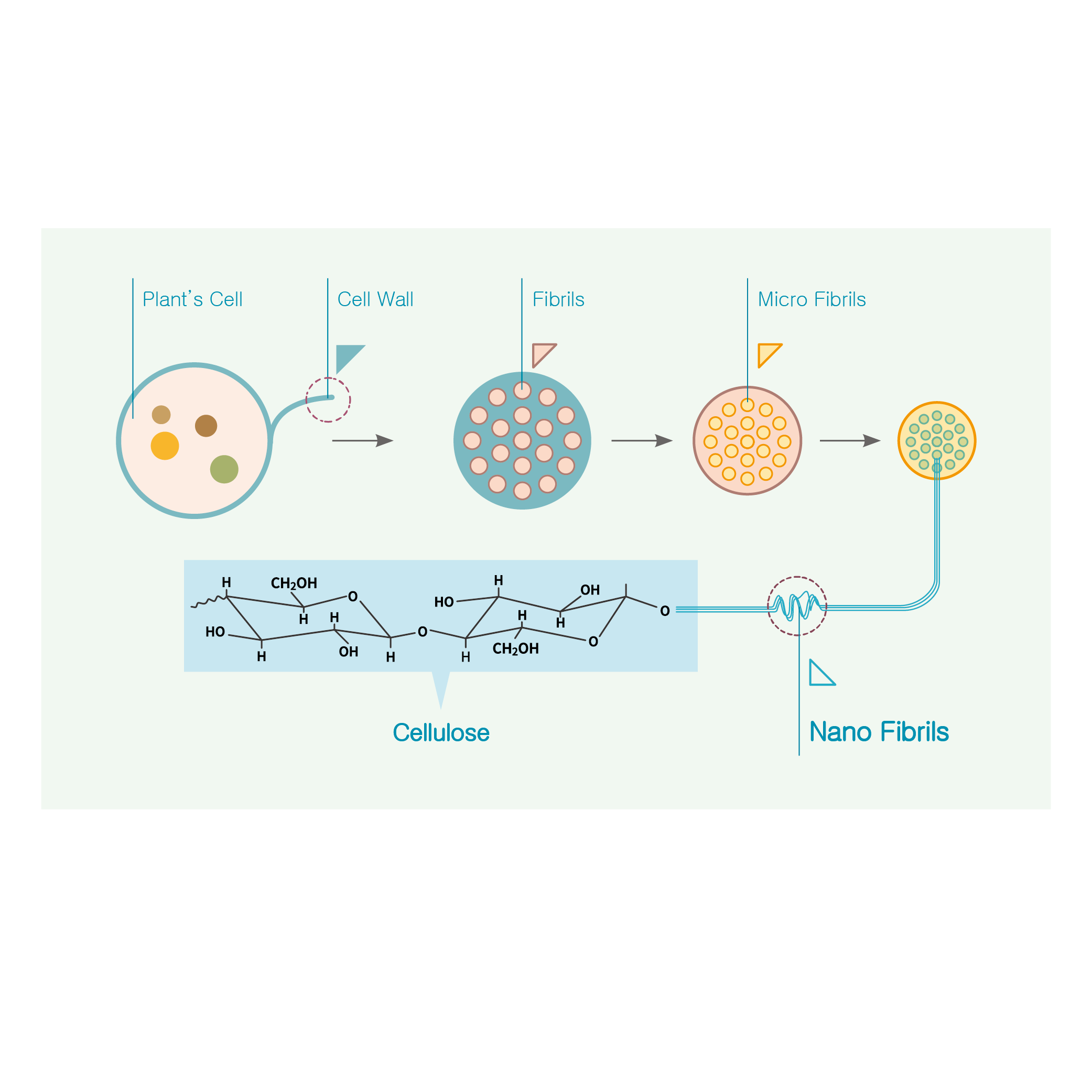

CNF (Cellulose Nano Fiber) is a future material that possesses a variety of materiality and it applies to a wide range of industries. It is an ultra-fine fiber made from plant fibers obtained from wood and thinned down to the nanometer (1/1 billionth). It weighs only one-fifth of steel, but its strength is 5 times stronger. It is a next-generation new material that succeeds carbon fiber.

CNF is a nanomaterial made of 'cellulose', a natural polymer that exists most abundantly in nature. Cellulose, the main component of plant cell walls, is a natural polymer material that is harmless to the human body and is more effective at 'nano' size than when it is micro in size.

High absorbers such as cosmetics,

antibiosis filters,

separation membrane

for a secondary battery.

Substitute for Carbon fiber,

biomimetic form, films,

electronic components

Paper, cement reinforcing agent,

food additive, thickened paint,

paper coating, composite agent

High absrbers such as csmetics,

Antibiosis filters,

Separatin membrane for a secondarybattery

Substitute for carbn fiber,

Biomimetic form, Films,

Electronic components

Paper, Cement reinforcing agent,

Food additive, thickened paint,

Paper coating, Composite agent

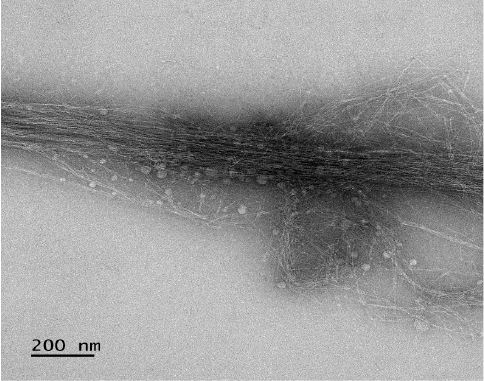

O-CNF

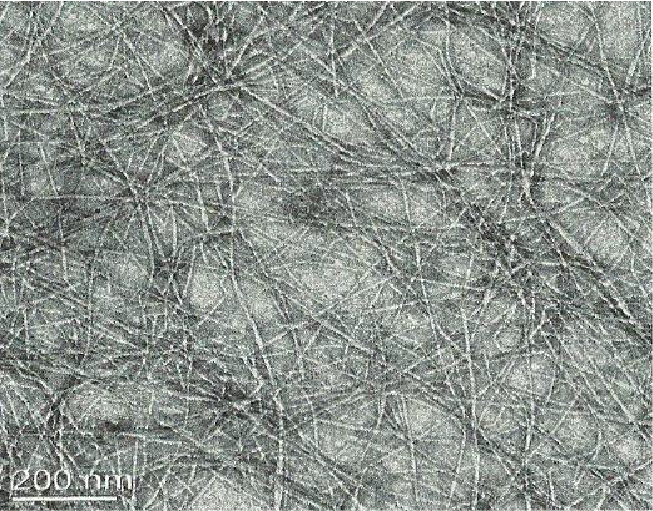

O-CNF is a highly refined form of CNF extracted from a specific non-lignocellulosic in the clean region of Shiva, Malaysia.

Compared to the existing linear CNF produced by developed countries, it is 5 to 50 nm in size, which is 1/10th the size of the existing CNF,

and it is a unique technology that only we have in the form of a mixed globular.

Carbon fiber is light and strong, but there is a risk of resource depletion because it is extracted from petroleum, whereas CNF can be extracted from weeds as well as wood pulp. Moreover, it is a material that has high viscosity and airtightness, maintains transparency, and is resistant to heat.

Larger surface area and maximizing

Larger surface area and maximizing Increase surface

Increase surface  Enhance dispersion stability by eliminating

Enhance dispersion stability by eliminating

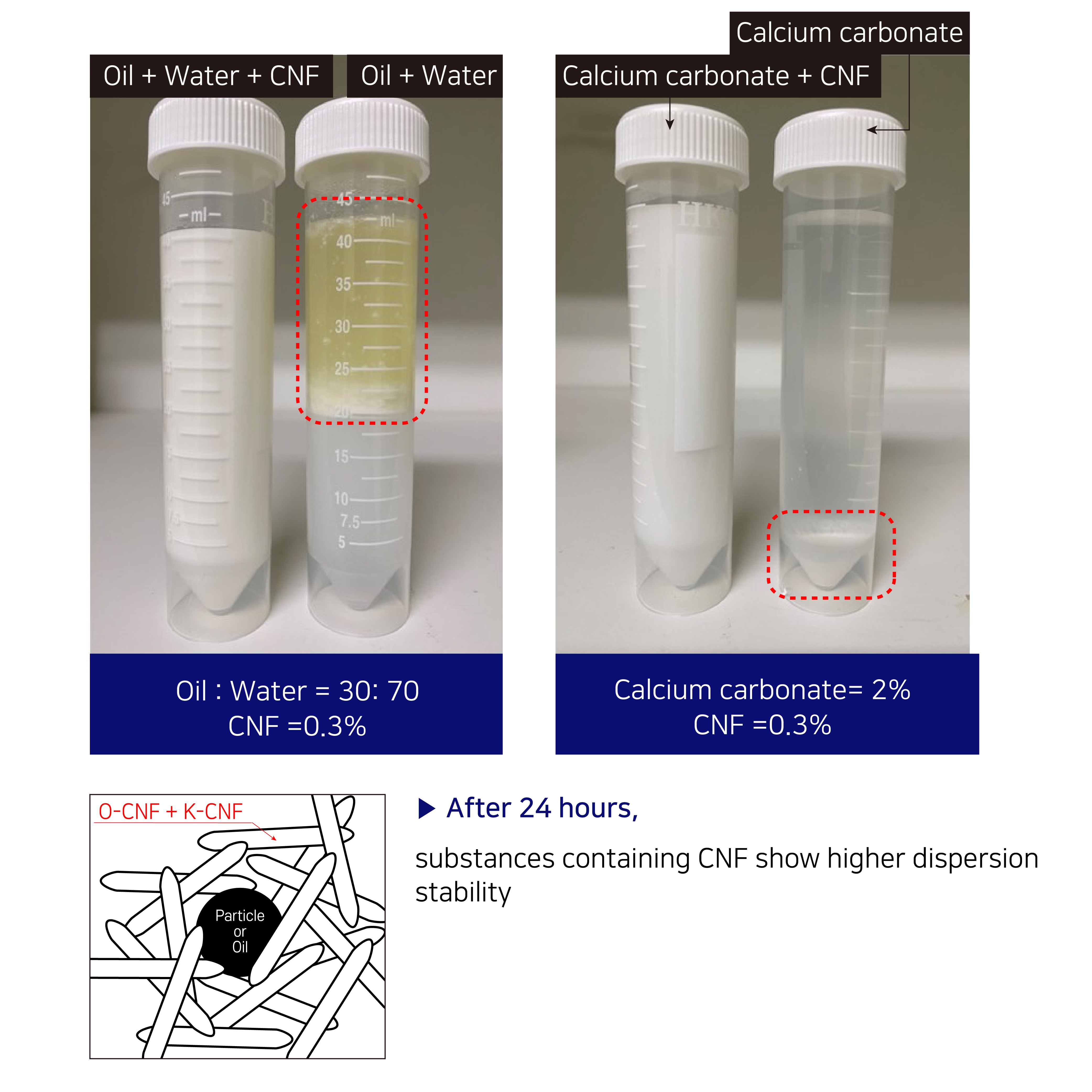

When used independently or mixed with K-CNF, our O-CNF forms a “three-dimensional mesh structure” that captures (isolates and confines) particles or oil droplets, thereby stabilizing the dispersion of the substance to be delivered.